Panel line

Simulation model for analyzing the storage and handling of steel plates in the steel stock yard of a shipyard. The model allows to evaluate situations in the implementation phase of the yard, as well as the operation strategies to reduce storage costs and risks of production stoppages. In the planning phase, the model supports the decisions associated with the definition of equipment, systems, treatment processes, as well as level of pavement and defining the storage areas. In the operation phase, the model allows evaluating the performance of the steel stock yard, involving: a study of pilling policies definition of contingency plans, evaluation of additional shifts and overtime, reallocating of underutilized areas.

Simulation model for analyzing the storage and handling of steel plates in the steel stock yard of a shipyard. The model allows to evaluate situations in the implementation phase of the yard, as well as the ope...

Sandblasting, painting, pre-erection and erection of ship blocks

Simulation models covering sandblasting process, painting, pre-erection and erection of ship blocks of a LNG ship. In this model ship detailed data have been considered in order to analyses deeply the influence of welding processes on the lead time. Moreover the model allows to analyses the influence of number and size of work teams working in the shipyards.

Simulation models covering sandblasting process, painting, pre-erection and erection of ship blocks of a LNG ship. In this model ship detailed data have been considered in order to analyses deeply the influence...

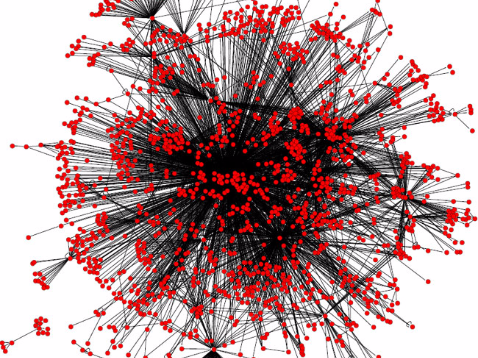

Ships and offshore structures complexity analysis model

Considering factors such as: Compactness complexity, assembly complexity, material complexity and shape complexity the project explore a not well developed area of engineering. The first step is analyse each production stage and look for the best alternative of performance using the concept of complexity as theoretical basis. Thereby it would be possible to do a well organized budget as well as a more optimum schedule, hence reducing many unnecessary expenditures that lower the productivity of shipyards. The innovative part of this project is that the usage of four different variables give the designer much more accuracy when developing the design and also enhances the possibility of finding problematic blocks that would reduce the performance when in more advanced stages. Futhermore, it aids the designer when comparing different possibilities of structure and choosing the more optimum.

Considering factors such as: Compactness complexity, assembly complexity, material complexity and shape complexity the project explore a not well developed area of engineering. The first step is analyse each pr...

Steel stock Yard

Simulation model for analyzing the storage and handling of steel plates in the steel stock yard of a shipyard. The model allows to evaluate situations in the implementation phase of the yard, as well as the operation strategies to reduce storage costs and risks of production stoppages. In the planning phase, the model supports the decisions associated with the definition of equipment, systems, treatment processes, as well as level of pavement and defining the storage areas. In the operation phase, the model allows evaluating the performance of the steel stock yard, involving: a study of pilling policies definition of contingency plans, evaluation of additional shifts and overtime, reallocating of underutilized areas.

Simulation model for analyzing the storage and handling of steel plates in the steel stock yard of a shipyard. The model allows to evaluate situations in the implementation phase of the yard, as well as the ope...

Block erection sequence optimization

Application of discrete event simulation in the planning and organization of workstations and integrated analysis of critical processes like assembling and blocks erection. Two fronts of analysis were established independently. The first corresponds to different alternatives for blocks assembly and the second corresponds to the block erection process. The model evaluates firstly the grouping of blocks in specific workstations and sizing of workstations. Then, some block erection strategies were evaluated (ring layer and pyramidal) measuring the use of resources and production times. This simulation model was coupled to a genetic optimization algorithm in order to find the best alternative to sequencing the blocks.

Application of discrete event simulation in the planning and organization of workstations and integrated analysis of critical processes like assembling and blocks erection. Two fronts of analysis were establish...

Assembly and pre-erection

Model involving the representation of assembly processes, pre-erection (large blocks), building and launching a series of Suezmax tankers in order to evaluate the capacity of the shipyard and risks of delay in completing the work.

Model involving the representation of assembly processes, pre-erection (large blocks), building and launching a series of Suezmax tankers in order to evaluate the capacity of the shipyard and risks of delay in ...

Port terminal simulation

Simulation model to analyze the efficiency of a terminal of port operations and bay plan arrangements of container ships. The model allows us to assess the efficiency of loading and unloading of a container ship considering different variables as tides, speeds of cranes, number of cranes working at the same time e arrangement of the containers on the ship. The model was calibrated with statistical data of seven months of operations provided by a terminal acting on Rio de Janeiro’s port and uses stochastic patterns to assign delay values such as defects, waiting for trucks and others. As results, we obtain the operation time, gross and net, the number of movements per crane and the utilization of each element of the simulation.

Simulation model to analyze the efficiency of a terminal of port operations and bay plan arrangements of container ships. The model allows us to assess the efficiency of loading and unloading of a container shi...