Simulation of production processes in naval construction

Currently the shipyards have devoted enormous effort to manage efficiently its resources such as manpower, workshops, cranes, conveyors, construction areas and building blocks, steel yards, among others. Usually planning is performed by an experienced manager of the shipyard and demands too long times to achieve planned results. Furthermore, the quality of the programmed results is not the best.

Applications involving Discrete Event Simulation (DES) are being employed in the shipbuilding industry in order to improve the overall process.

Simulation involves modeling a process or system, such that the model represents the responses of the real system in a sequence of events that occur over time. In this way, we obtain answers supported by the computer to critical issues such as: when and where to produce what and with what resources, depending on availability and restrictions of resources and materials. The use of virtual reality technologies results in a higher efficiency in terms of production planning and strategy work, offering as a result, significant productivity gains.

The simulation of production processes is an emerging tool and has great potential to assist engineers and managers in strategic and operational planning. This tool certainly can assist in the analysis of complex processes and decision making.

The LABSEN develops simulation models of shipbuilding processes using the softwares Arena and Delmia Quest.

Simulation of logistic in port systems

The Discrete Event Simulation (DES) is traditionally used for performance analysis of port terminals. First applications took place at 1960s, in the evaluation of ore port terminals.

Ports are dynamic and complex systems, involving various elements interacting with each other and influenced by effects of random nature. Situations like this pose serious difficulties for an analytical study of the problem, making the modeling and computer simulation technique a strong ally for the design and analysis of logistics systems.

In the case of specialized terminals in container handling, the use of simulation enables the analysis of strategies that improve the efficiency of port operations. This improve involves, for example, the increase of container handling capacity in port terminals and reduction of the operating time of ships.

The LABSEN develops simulation models of port systems using the softwares Arena and Delmia Quest.

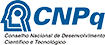

Simulation of logistic from support to offshore operations

The realization of offshore exploration and production of oil and gas involves, among other resources, port terminals, platforms, maritime supply boats and relief ships. They are resources of high cost and whose best use provides substantial savings.

Currently, it is still very common to use empirical methods in the planning of offshore activities, which makes the operations little optimized.

The discrete event simulation allows properly model the offshore operations characterized by stochastic events and strongly affected by environmental factors in order to obtain the best alternatives of resources use.

The LABSEN develops simulation models of offshore logistic using the softwares Arena and Delmia Quest.

Welding simulation

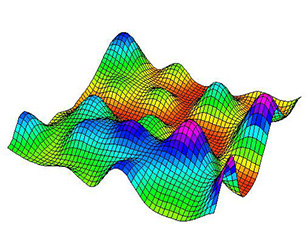

Manufacturing distortions and residual stresses constitute a serious problem existing in engineering areas in which heat is used in the manufacturing process, but in no area exerts as much influence as in naval and offshore construction.

The naval industry makes heavy use of welding for construction of large panels that make up the ships and offshore structures.

The welding simulation, which can be realized in softwares such as Virfac Welding, enables to understand the impact of the welding in the production process and, thus, evaluate residual stresses and deformations produced when manufacturing the panels. The optimization of process parameters and welding sequences increases product quality.

Process optimization

Optimize corresponds to plan or develop with maximum efficiency a particular activity or process.

Simulation tools such as Delmia Quest software, allow to assess the behavior of a model starting from conditions and scenarios previously established. However, the simulation is not a method used strictly for process optimization.

The use of optimization tools, like ModeFRONTIER, combined with simulation packages, potentiates the use of these tools for improving production processes.